Been there, done that, would do it again in an instant.

Enjoy your beer mate!

Been there, done that, would do it again in an instant.

Enjoy your beer mate!

Well that was the problem, thanks for everyone’s input.

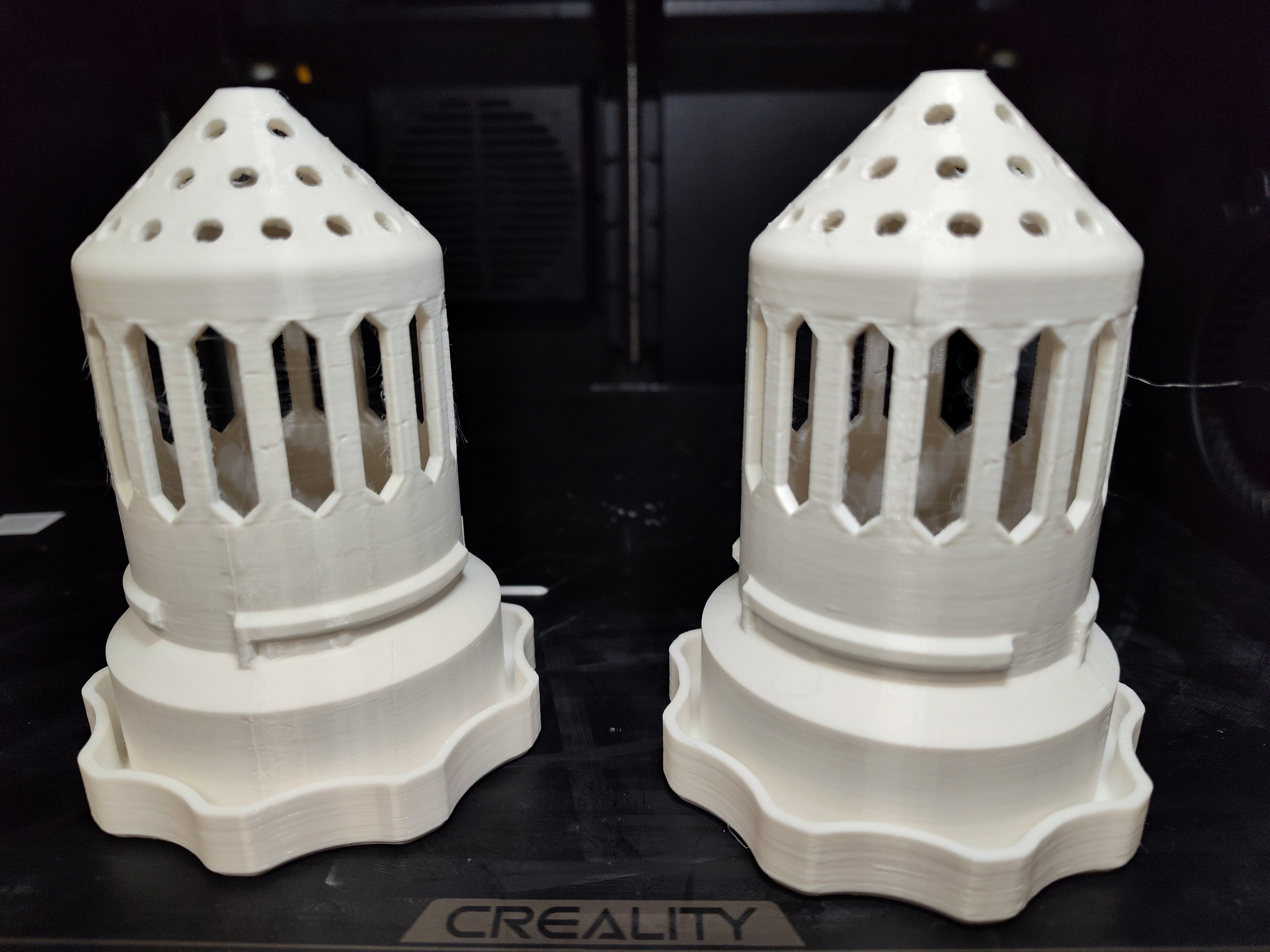

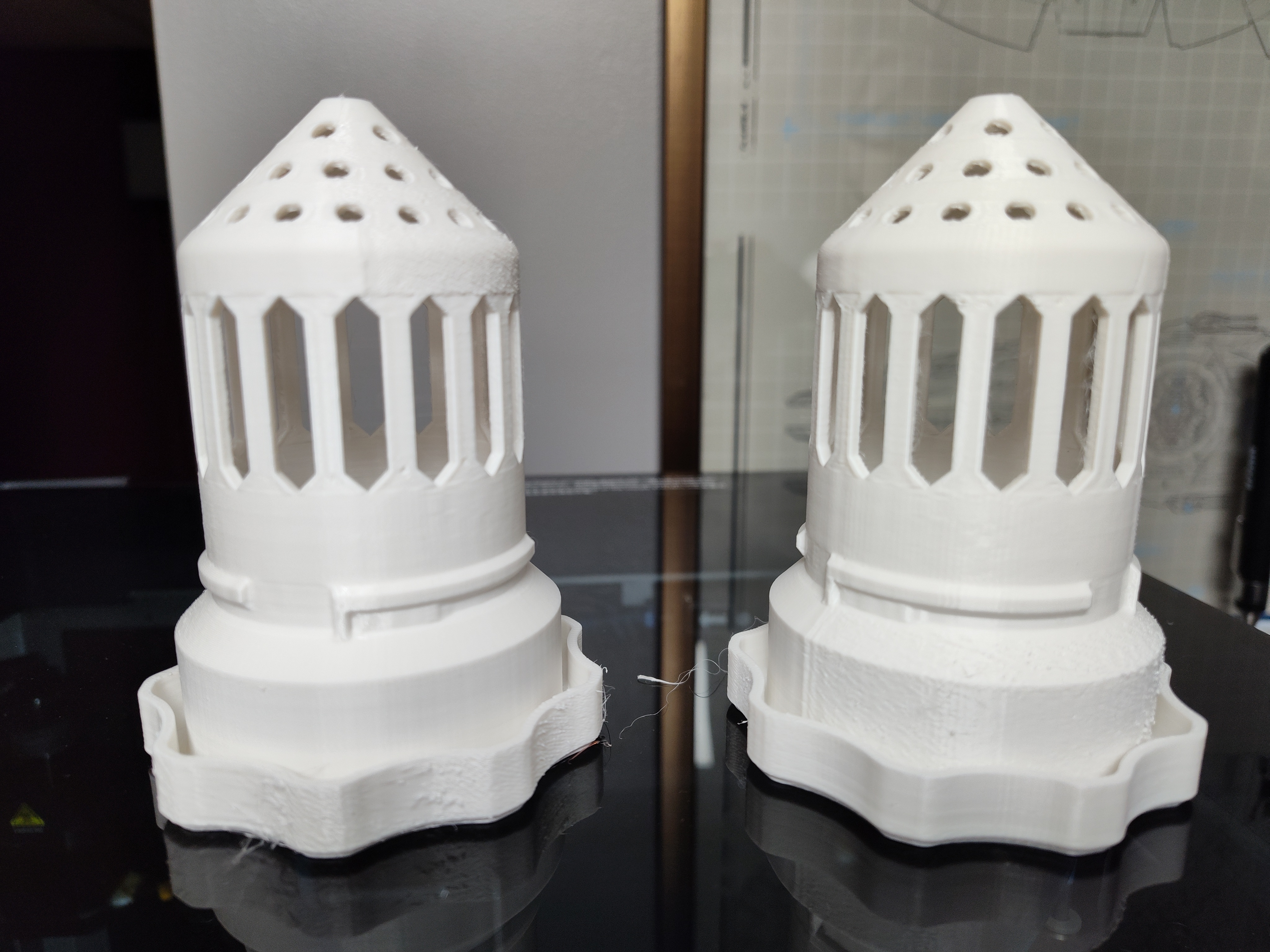

So I sliced and printed a different model, and then rotated 1 by 180°, it is somewhat weird as the lowest part on the right model seems ok but as the wall built up on the inside it was getting the artifacts. The model on the left was getting the artifacts on the outer piece but not the inner.

In rotating the models after, the artifacts are on the opposite side.

I noticed it was starting at the seam, I have the scarf joint on contour, and noticed that “scarf around entire wall” was checked so trying reprinting to see if that is the issue.

Good point, I have mainly been printing these items for the hydroponic tower. I do have other versions that I can check. I think after this set prints I will add some basic shapes in different orientations to see if there is issues still.

That being said I did print some other items that were stacked and each one is much thinner but there are no artifacts on the outer walls.

I re-lubed the rods before starting another set and still having the issue. I was thinking it had something to do with the Bowden tube but even at the back where the tube doesn’t move much the issue still happens.

Is there a specific lube that is better than others?

Thanks for your reply, to your point yes they still fit, been having this issues for a bit now as I’m up to about 40 of these netcups and the associated other pieces for the grow towers.

I think the belts are good, but will double check.

Depending on how close you are to you friends you can look at Grohman

https://grohmannknives.com/index.php/products/kitchen

The are based on Nova Scotia.

Easy there pussies can be useful, unlike that shitheel.

Funny and sad that the Canadian taxpayers are footing the bill for some friend of a friend to have a luxury condo in NYC. These so called leaders are just milking everyone. What a disgrace.

Well of course they did😔, corporations will exploit every little opportunity, in turn they line up cushy roles for slimy politicians in exchange for not fixing these “loopholes”.

I can’t speak to multi colour perse, however the creality K2 went on sale today for certain countries and they have a 50% off sale for a limited number of units, they sold out today’s stock but will have it again tomorrow then they will drop to 40% then 30%. Might be good if your willing to be a beta tester essentially.

The Prusa units seems to waste less filament.

https://youtu.be/DUvkz-XcYRs?si=R6Z63zq1g9rEhnfH

I think this might be a method.

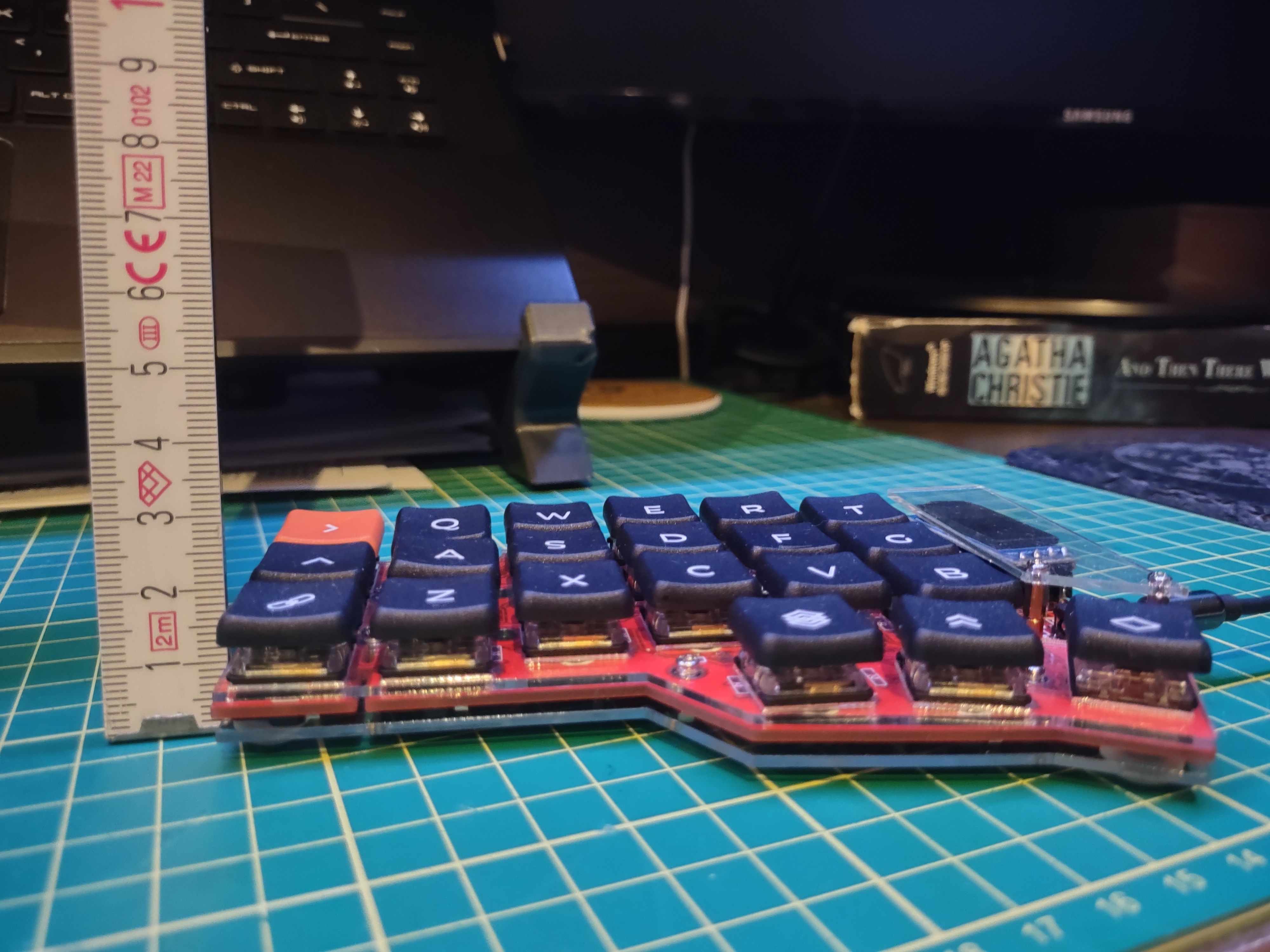

I cannot comment on the noise of the Kailh browns at the moment as the board has been giving me some grief and I am waiting on new Elite-C controllers from Omega Keys. The keycaps came from ChocFox, the PCBs were ordered directly from JLCPCB using Foostans design, everything else was mainly through amazon. As for the acrylic, I have my own CO2 laser and just cut them out of 1.5mm clear, also from Foostans GitHub repository.

There are several good tutorials out there with parts lists and the build process, Marek Piechut has a good one called Corne MX 3.0 Keyboard Build Guide.

I wanted something super thin so soldered the controller to the board, I do not suggest this as I had some errors on my part and destroyed the controller, thus I’m waiting for two new ones before I can use the board, until then I’m stuck with my hand wired dactyl manuforms.

Just make sure you know what board and keycaps you want, sounds like the Corne chocolate to me, and pay close attention to the LEDs if you go that route, I have 600 that are of no use to me and am waiting on the proper ones.

Other than that have fun and there are plenty of people willing to offer help and advice between here and Discord.

I’m building a low pro Corne, Kailh browns with ChocFox keycaps, it’ll be my travel keyboard.

I am using Elite C’s.

Almost forgot, Teaching Tech has a great calibration web site and YouTube channel.

My first suggestion if you have a Raspberry Pi Zero 2w or better is to install Klipper. If that isn’t a route to go down for you then Myers firmware was really good (not sure if it’s still around since I went to Klipper).

I’ve printed so many miss for mine, spool holder moves to the side, filament guides, different spool holders with bearings, new hot end fan assemblies ,small tool holder that slides into the v slots. Covers for the V slots.

It’s a great machine to learn and tinker on, some people don’t like that but I really enjoyed it.

I’ve since switched to direct drive instead of the Bowden tube and added another Z rod and stepper. I have a microswiss all metal hotend which has been fantastic and I have put Noctua fans for the heat break. Also upgrade the Bowden tube to the Capricorn type, it is much better.

A magnetic build plate from Biqu was another good addition.

Almost forgot, I printed risers for the feet out if TPU and that seems to help, I probably would have tried the ones that the squash balls go into but these work fine. In order to print TPU with the Bowden tube you need to print slow.

Also keep an eye on the plastic handle on the filament extruder, they are known to be weak and crack, a good aluminum dual gear is a good low cost investment.

Search on Thingiverse and Printables for mods for the Ender 3 and you will be overwhelmed with your options.

Patience is a virtue, and remember there are no stupid questions and a huge community of people willing to help.

If there is anything else I can do to help, don’t hesitate to ask.

That sounds like an interesting plan, my E stepper driver was what acted up on my 4.2.2, it seems to be working now, but I’d like to see your config in case I need to go in that direction.

Update:

I took everyone’s advice and tried all the suggestions. In the end I completely disassembled the printer and made sure everything was square or perpendicular where it needed to be. I think maybe the dual z screws were binding, although when I took everything apart I noticed that I did not use the Y cable for both z steppers, I ran the original short cable to one motor and

the Y to another, not sure if that had any effect or not, but now the Y cable is running both z steppers.

It does seem to be better, but I still have the dip in the bed, which is still a bit of an issue for the BL Touch, but not nearly as bad as before. I may have slightly bowed it when trying to crank down the levelling wheels.

I think that the z screws were binding just enough that it couldn’t keep up with the micro adjustments, I guess time will tell.

Thanks for everyone’s input and advice, hopefully it’ll run for a couple more years. If not then a replacement Bamboo might be in order.

Now I just need my resin printers to stop failing prints, but I think that’s more me than the printers. lol

Thanks everyone.

https://hackaday.com/2022/09/05/food-safe-3d-printing-a-study/