“This breakthrough development translates into a remarkable improvement in cell-core energy density, reaching 2,000Wh/L in batteries and approximately 1,700Wh/L in full-size EV batteries – more than double the performance of current state-of-the-art technologies,”

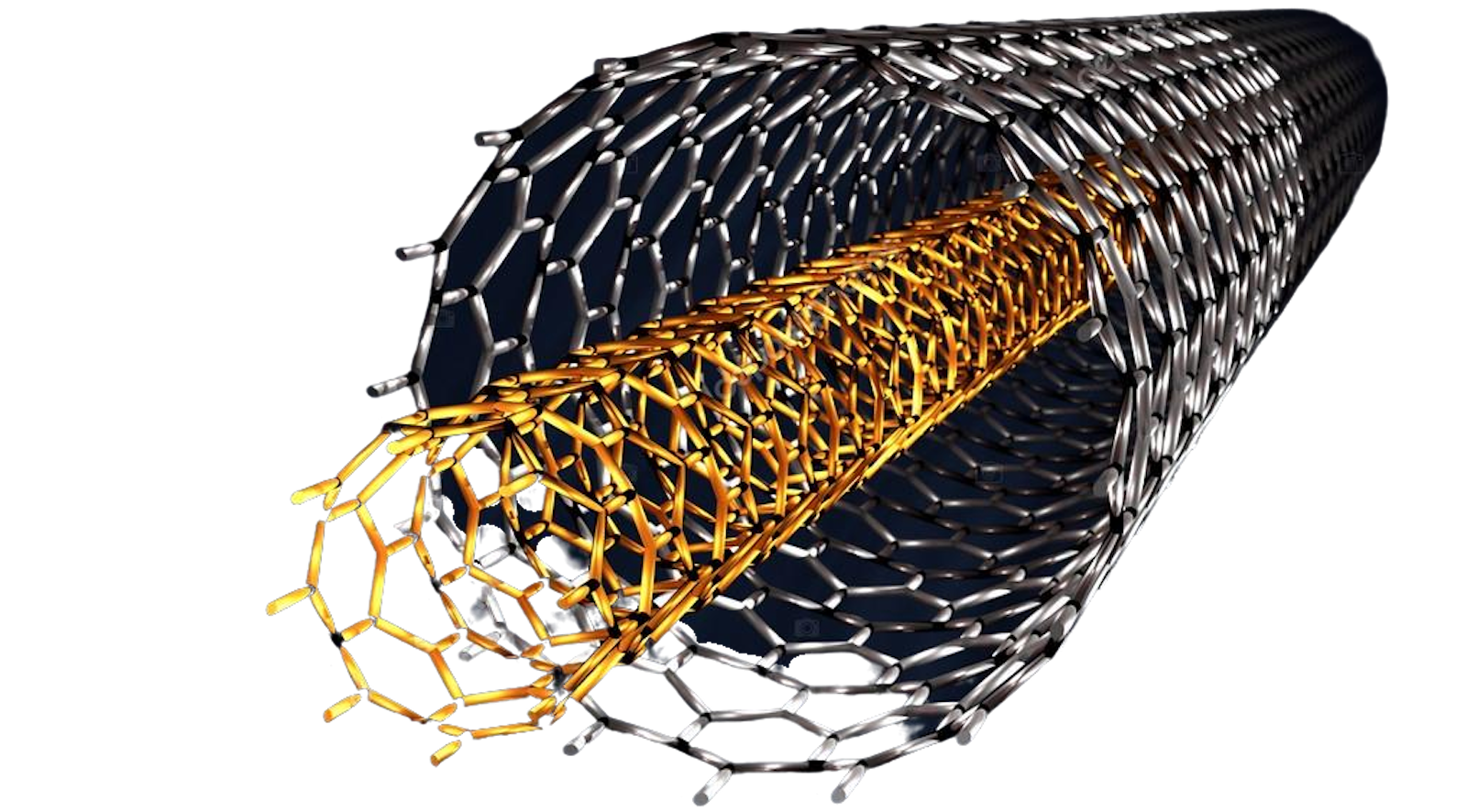

“Sienza’s 3D pure silicon anode has demonstrated an average gravimetric capacity of 2,941 mAh/g,” Professor Gharib said. “This means that for every gram of silicon, our batteries can store 2,941 milliampere-hours of electricity, significantly higher than the industry standard for graphite, with a gravimetric capacity of 372 mAh/g.”

Aside from completely avoiding the cobalt issue, Sienza notes that its manufacturing process does not rely on the solvent-based coating systems deployed for producing conventional lithium-ion batteries. Sienza cites one commonly used solvent in particular, N-methyl-pyrrolidone (NMP).

Thank you for that additional info. I’m highly intrigued with this because vehicles would “refuel” in a familiar way, and there could be a choice to also plugin recharge if someone had their own facilities, at home or work.

It might be the bridge needed to entice more conversions, and might improve with experience and time, much as ICE have done since the Model T.